The Ativa represents many firsts for Perodua. In this article, we break down the unique mechanism of its CVT transmission, the brand's first turbocharger and the DNGA chassis it shares with Daihatsu.

Words: Arif Sharif

CVT Transmission

The Ativa’s CVT is no ordinary CVT; it’s actually Daihatsu’s D-CVT or Dual mode CVT. It comprises of a split gear setup; the conventional belt-pulley setup is still present, but there are additional gears to the pulley. A clutch pack has also been added to engage and disengage the split gears.

The purpose behind this setup is to eliminate the most common flaw of CVTs – the rubberband effect. This is because CVTs attempt to maintain the engine rpms constantly at its optimum power band. In keeping the revs from fluctuating, some CVTs create an unpleasant noise – a cry for help of sorts. Additionally, as CVTs provide infinite ratios by constantly varying the pulley diameter, this introduces power loss to friction between the belt and pulley.

D-CVT is Daihatsu’s ingenious concept to get around this conundrum. The perk of this setup is that the transmission is not perpetually driving on belt-pulley alone like conventional CVTs. Rather, at higher speeds, the clutch pack automatically engages the split gear. This translates to reduced power loss from belt-pulley friction and less CVT drone at high speed. When the vehicle speed drops, the clutch will disengage, reverting to belt-drive.

During our test drive, the CVT noise is largely absent even when we buried the throttle to the floor. The engine is pleasantly quiet and responsive to all the demands of our right foot, resulting in effortless overtaking and highway cruising.

However, D-CVT should not be mistaken for Toyota’s Direct Shift-CVT. Where Daihatsu’s D-CVT switches from belt drive to split gear at higher speed, Toyota’s Direct Shift-CVT engages the so-called ‘launch gear’ at a lower speed to improve launch response from a standstill. It then switches over to belt drive at high speed, engaging the ‘launch gear’ only after the vehicle grinds to a halt.

The Direct Shift-CVT is not fitted on the Ativa because the former is engineered for Toyota’s Dynamic Force Engine. Plonk the Dynamic Force Engine into the Ativa and the D-CVT is no longer suitable due to its torque limit of 150 Nm; the Dynamic Force Engine makes 205 Nm, exceeding D-CVT’s torque limit. Only Toyota’s higher-end models, such as the TNGA-K-based Toyota RAV4 and Harrier are equipped with Direct Shift-CVT.

Turbocharged Engine

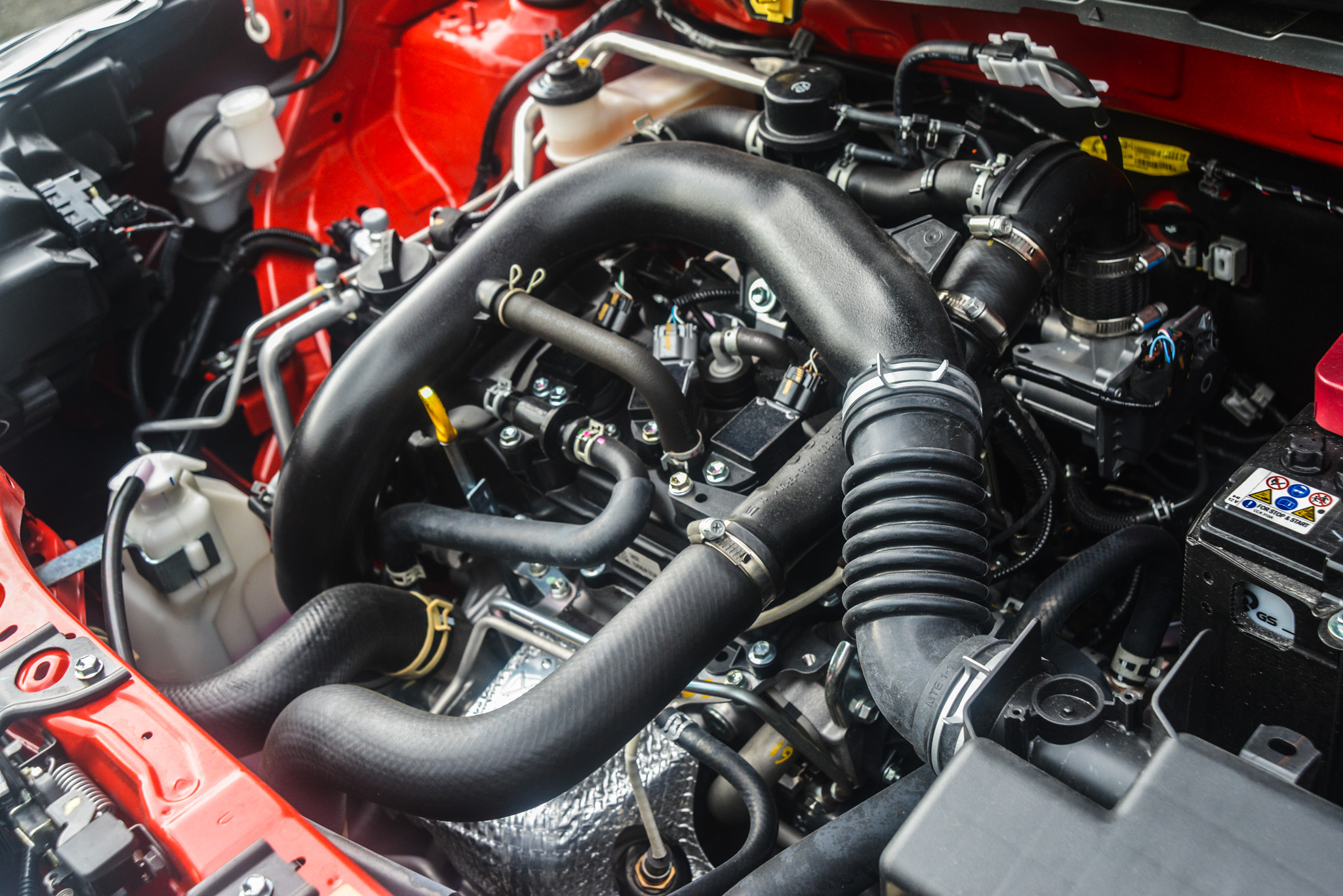

The engine found under the Ativa’s bonnet is the single-scroll turbo 1.0-litre 1KR-VET three-cylinder unit that makes 96PS and 140Nm of torque. This marks Perodua’s first foray into the downsized turbocharged engine bandwagon.

The 1KR-VET is part of Toyota’s KR engine family, which includes the 1KR-VE naturally aspirated unit used in the Axia and Bezza. They have the same aluminium block, cylinder count, timing chain, dual overhead cam, four valves per cylinder, and 71mm bore, but their similarities end there.

The 1KR-VET unit boasts a smaller displacement of 996cc – two cubic centimetres less than the rest of the KR line-up. This is due to its 0.1mm shorter stroke than the rest (83.9mmvs 84mm). Incidentally, the 1KR-VET has a lower compression ratio of 9.5:1 as opposed to 11.5:1. This is to keep engine knock at bay due to higher cylinder pressure that turbocharging presents. The variable intake valve timing from the Bezza/Axia has been carried over to the Ativa.

The Ativa’s engine boasts some clever tech as well. The port-injected mill is armed with dual injectors (two fuel injectors per cylinder) and dual intake ports (two intake ports per cylinder). Splitting the ports into two separate paths ensure efficient mixing of air and fuel by reducing turbulence in the intake ports, hence greater fuel atomisation.

There’s also multi-spark ignition, which should not be confused with twin spark plugs; rather the spark plug fires twice in quick succession. The second spark adds more power to the flame initiated by the first spark. This ensures the flame will spread across the cylinder quicker to burn every last bit of fuel mixture.

On the exhaust side, the exhaust ports merge into a single opening. Combine this with the catalytic converter just downstream from the exhaust manifold, and exhaust gas temperature will increase faster. As a result, the catalytic converter will warm up faster and greatly lower start-up emissions.

Being a three-cylinder mill, vibration is the most common concern. However, we didn’t notice much of it during our test drive. When idling, the dashboard rattle is virtually non-existent. Give it the beans and all three cylinders fire away without noticeable delay. Moreover, its auto start-stop system is impeccably smooth as the engine doesn’t jerk when it restarts. This makes the feature more liveable in urban environments.

To add to the savings, the annual road tax for a 996cc engine is merely RM20 versus the Proton X50’s RM90.

DNGA Chassis

Short for Daihatsu New Global Architecture, the platform underpinning the Ativa is basically a modular architecture built on a unibody chassis that has been around since 2019. It represents a technological step forward for Perodua, bringing it one step closer to aligning its cars with the latest engines, transmissions, chassis, and connectivity technology from Daihatsu. It is also a big step forward in futureproofing as DNGA is a CASE-ready (Connected, Autonomous, Shared, Electrification) architecture. This could mean hybrid, full EV, and self-driving Perodua vehicles in the not-too-distant future.

From an industrial standpoint, modularity is great for economies of scale as it allows for more shared parts between new models. DNGA will underpin Daihatsu’s entire range of cars, including DNGA-A and DNGA-B, built for both domestic and international markets. If future Perodua models are DNGA-based, it will cut the company’s manufacturing costs significantly, making its future models more affordable.

A chassis is not complete without its suspension. Just like the Rocky and Raize, the Ativa rides on front MacPherson Strut and torsion beam in the rear. The suspension has been commendably tuned to soak up surface imperfections – a lifesaver on Malaysia’s pockmarked roads. As we discovered during the test drive, the Ativa remains brilliantly composed even when this writer purposely ran over sharp road humps. Additionally, the DNGA-based suspension sees a reduction in the number of moving parts, which helps keep the weight and complexity down.

Safety has been improved as well. The DNGA platform sees up to 10 percent more application of thicker, stronger high-tensile steel on the upper body. The force-application point has been modified at the front and rear to ensure uniform distribution of crash force throughout the chassis. This confers better underbody’s collision safety performance. Combine the strength of DNGA chassis with ADAS across Ativa’s model range, it’s an affordable car with a five-star NCAP rating. Crucially, it offers an alternative to Proton X50 as the latter only has ADAS on its range-topping Flagship.